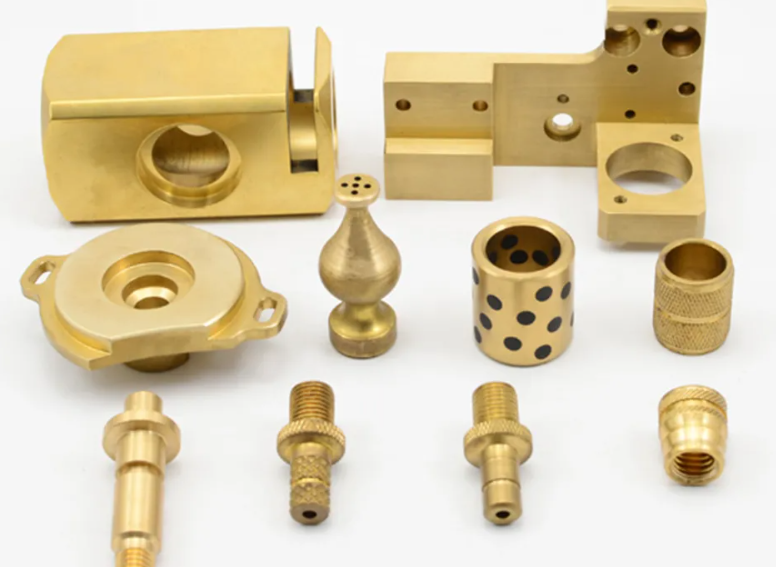

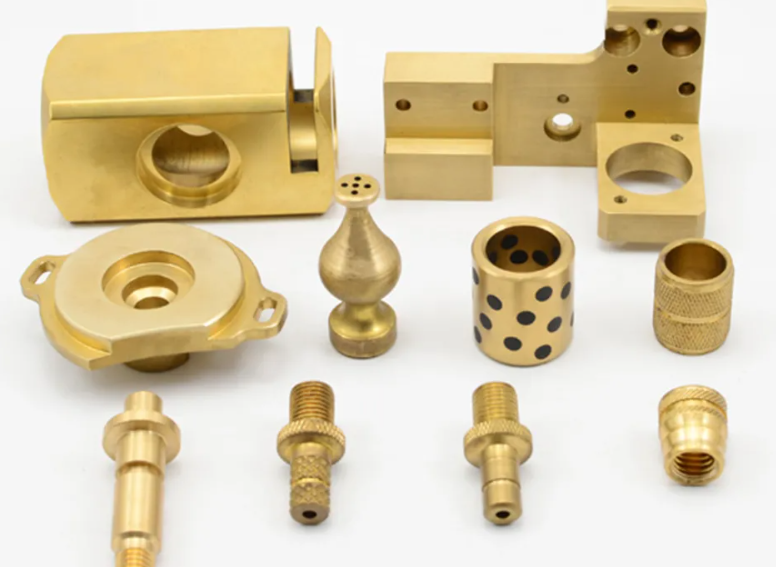

Product Description

XINMEI CNC MACHINING–YOUR ONE-STOP CUSTMIZED MACHINING SERVICES

Company Profile

| Inspection Devices For Quality Control |

Overview

| Who we are | 8+ Years Experienced and Professional Factory for One-Stop CNC Machining Services |

| What we do | CNC Machining Services: CNC Milling Parts CNC Turning Parts CNC Grinding Parts Auto Lathe Parts Stamping Metal Parts |

| What is important | 1. Price above is not final order price which need to re-calculate CZPT your detailed requirements. 2. Please provide your detailed drawings CAD/DXF/STP rough drawings for engineer team to involve and come up with processing and quotes. 3. Sample is always needed for confirmation before mass production. 4. To cancel the order is not supported once confirmed due to its customization. |

| Why Choose us |

1. 8+ years professional CNC Machining services 2. Experienced engineering team 3. Competitive factory price 4. Bubble bags+ Carton packaging for no scratches, fast & safe delivery 5. Stand-by forever |

| QC Control | 100% inspection on all aspects (dimension, surface treatment etc..) |

| Testing/Inspection Devices | MMD-100b Profilemeter/Video Measuring Machine/CNC Vision Measuring Machine Sinpo CZPT 300C Three Dimensional/Calipers/Micrometer/Altimeter/Pin Gauge/Inside Micrometer/Roughness Tester etc. |

Product Description

| Product Name | Custom Lathe Parts Automotive Accessories Stainless Steel Precise CNC Machining Car Drive Shafts |

| Processing | CNC Machining, Drilling, Turning, Milling, Grinding, Stamping etc.. |

| Treatment | Polishing, Sandblasting, Anodizing, Electroplating, Electrophoresis, Spraying, Silk printing, Laser Spraying/Etching etc. |

| Material | Aluminum/Alloy/Steel/Iron/Brass/all metals |

| Tolerance | ±0.01 mm |

| Drawing | CAD/DXF/STP/rough drawings |

| Service | All Customized CNC Machining Services |

Product Types

For more products, please click here

FAQ

| Q1: Are you a factory or trading company? | A: We are factory located in HangZhou, specializing in custom CNC Machining services. |

| Q2. Can you produce according to samples if no drawing? |

A: Yes, we have professional engineer to work out drawings according to your sample. |

| Q3. How long can i get reply? |

A: We will reply within few minutes in working times and within 24 hours in holidays. |

| Q4: What is your sample policy? |

A: Sample cost will be charged for customization but will refund in mass order. |

| Q5: What is the lead time for both sampling and production? |

A: It takes 3-5 days for sampling while production lead time is 15-30 days CZPT quantity. |

| Q6: What is your payment terms? |

A: We accept 50% as deposit and 50% balance before shipment. |

| Q7: What is your MOQ? |

A: 1000 pcs above is suggested for customization with molding. |

Any concerns, please feel free to contact us! Thank you! /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard Or Nonstandard: | Nonstandard |

|---|---|

| Shaft Hole: | 8-24 |

| Torque: | Customized |

| Bore Diameter: | Customized |

| Structure: | Rigid |

| Material: | Stainless Steel |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do drive shafts handle variations in speed and torque during operation?

Drive shafts are designed to handle variations in speed and torque during operation by employing specific mechanisms and configurations. These mechanisms allow the drive shafts to accommodate the changing demands of power transmission while maintaining smooth and efficient operation. Here’s a detailed explanation of how drive shafts handle variations in speed and torque:

1. Flexible Couplings:

Drive shafts often incorporate flexible couplings, such as universal joints (U-joints) or constant velocity (CV) joints, to handle variations in speed and torque. These couplings provide flexibility and allow the drive shaft to transmit power even when the driving and driven components are not perfectly aligned. U-joints consist of two yokes connected by a cross-shaped bearing, allowing for angular movement between the drive shaft sections. This flexibility accommodates variations in speed and torque and compensates for misalignment. CV joints, which are commonly used in automotive drive shafts, maintain a constant velocity of rotation while accommodating changing operating angles. These flexible couplings enable smooth power transmission and reduce vibrations and wear caused by speed and torque variations.

2. Slip Joints:

In some drive shaft designs, slip joints are incorporated to handle variations in length and accommodate changes in distance between the driving and driven components. A slip joint consists of an inner and outer tubular section with splines or a telescoping mechanism. As the drive shaft experiences changes in length due to suspension movement or other factors, the slip joint allows the shaft to extend or compress without affecting the power transmission. By allowing axial movement, slip joints help prevent binding or excessive stress on the drive shaft during variations in speed and torque, ensuring smooth operation.

3. Balancing:

Drive shafts undergo balancing procedures to optimize their performance and minimize vibrations caused by speed and torque variations. Imbalances in the drive shaft can lead to vibrations, which not only affect the comfort of vehicle occupants but also increase wear and tear on the shaft and its associated components. Balancing involves redistributing mass along the drive shaft to achieve even weight distribution, reducing vibrations and improving overall performance. Dynamic balancing, which typically involves adding or removing small weights, ensures that the drive shaft operates smoothly even under varying speeds and torque loads.

4. Material Selection and Design:

The selection of materials and the design of drive shafts play a crucial role in handling variations in speed and torque. Drive shafts are typically made from high-strength materials, such as steel or aluminum alloys, chosen for their ability to withstand the forces and stresses associated with varying operating conditions. The diameter and wall thickness of the drive shaft are also carefully determined to ensure sufficient strength and stiffness. Additionally, the design incorporates considerations for factors such as critical speed, torsional rigidity, and resonance avoidance, which help maintain stability and performance during speed and torque variations.

5. Lubrication:

Proper lubrication is essential for drive shafts to handle variations in speed and torque. Lubricating the joints, such as U-joints or CV joints, reduces friction and heat generated during operation, ensuring smooth movement and minimizing wear. Adequate lubrication also helps prevent the binding of components, allowing the drive shaft to accommodate speed and torque variations more effectively. Regular lubrication maintenance is necessary to ensure optimal performance and extend the lifespan of the drive shaft.

6. System Monitoring:

Monitoring the performance of the drive shaft system is important to identify any issues related to variations in speed and torque. Unusual vibrations, noises, or changes in power transmission can indicate potential problems with the drive shaft. Regular inspections and maintenance checks allow for the early detection and resolution of issues, helping to prevent further damage and ensure the drive shaft continues to handle speed and torque variations effectively.

In summary, drive shafts handle variations in speed and torque during operation through the use of flexible couplings, slip joints, balancing procedures, appropriate material selection and design, lubrication, and system monitoring. These mechanisms and practices allow the drive shaft to accommodate misalignment, changes in length, and variations in power demands, ensuring efficient power transmission, smooth operation, and reduced wear and tear in various applications.

Can you provide real-world examples of vehicles and machinery that use drive shafts?

Drive shafts are widely used in various vehicles and machinery to transmit power from the engine or power source to the wheels or driven components. Here are some real-world examples of vehicles and machinery that utilize drive shafts:

1. Automobiles:

Drive shafts are commonly found in automobiles, especially those with rear-wheel drive or four-wheel drive systems. In these vehicles, the drive shaft transfers power from the transmission or transfer case to the rear differential or front differential, respectively. This allows the engine’s power to be distributed to the wheels, propelling the vehicle forward.

2. Trucks and Commercial Vehicles:

Drive shafts are essential components in trucks and commercial vehicles. They are used to transfer power from the transmission or transfer case to the rear axle or multiple axles in the case of heavy-duty trucks. Drive shafts in commercial vehicles are designed to handle higher torque loads and are often larger and more robust than those used in passenger cars.

3. Construction and Earthmoving Equipment:

Various types of construction and earthmoving equipment, such as excavators, loaders, bulldozers, and graders, rely on drive shafts for power transmission. These machines typically have complex drivetrain systems that use drive shafts to transfer power from the engine to the wheels or tracks, enabling them to perform heavy-duty tasks on construction sites or in mining operations.

4. Agricultural Machinery:

Agricultural machinery, including tractors, combines, and harvesters, utilize drive shafts to transmit power from the engine to the wheels or driven components. Drive shafts in agricultural machinery are often subjected to demanding conditions and may have additional features such as telescopic sections to accommodate variable distances between components.

5. Industrial Machinery:

Industrial machinery, such as manufacturing equipment, generators, pumps, and compressors, often incorporate drive shafts in their power transmission systems. These drive shafts transfer power from electric motors, engines, or other power sources to various driven components, enabling the machinery to perform specific tasks in industrial settings.

6. Marine Vessels:

In marine applications, drive shafts are commonly used to transmit power from the engine to the propeller in boats, ships, and other watercraft. Marine drive shafts are typically longer and designed to withstand the unique challenges posed by water environments, including corrosion resistance and appropriate sealing mechanisms.

7. Recreational Vehicles (RVs) and Motorhomes:

RVs and motorhomes often employ drive shafts as part of their drivetrain systems. These drive shafts transfer power from the transmission to the rear axle, allowing the vehicle to move and providing propulsion. Drive shafts in RVs may have additional features such as dampers or vibration-reducing components to enhance comfort during travel.

8. Off-Road and Racing Vehicles:

Off-road vehicles, such as SUVs, trucks, and all-terrain vehicles (ATVs), as well as racing vehicles, frequently utilize drive shafts. These drive shafts are designed to withstand the rigors of off-road conditions or high-performance racing, transmitting power efficiently to the wheels and ensuring optimal traction and performance.

9. Railway Rolling Stock:

In railway systems, drive shafts are employed in locomotives and some types of rolling stock. They transfer power from the locomotive’s engine to the wheels or propulsion system, enabling the train to move along the tracks. Railway drive shafts are typically much longer and may have additional features to accommodate the articulated or flexible nature of some train configurations.

10. Wind Turbines:

Large-scale wind turbines used for generating electricity incorporate drive shafts in their power transmission systems. The drive shafts transfer rotational energy from the turbine’s blades to the generator, where it is converted into electrical power. Drive shafts in wind turbines are designed to handle the significant torque and rotational forces generated by the wind.

These examples demonstrate the broad range of vehicles and machinery that rely on drive shafts for efficient power transmission and propulsion. Drive shafts are essential components in various industries, enabling the transfer of power from the source to the driven components, ultimately facilitating movement, operation, or the performance of specific tasks.

Can you explain the different types of drive shafts and their specific applications?

Drive shafts come in various types, each designed to suit specific applications and requirements. The choice of drive shaft depends on factors such as the type of vehicle or equipment, power transmission needs, space limitations, and operating conditions. Here’s an explanation of the different types of drive shafts and their specific applications:

1. Solid Shaft:

A solid shaft, also known as a one-piece or solid-steel drive shaft, is a single, uninterrupted shaft that runs from the engine or power source to the driven components. It is a simple and robust design used in many applications. Solid shafts are commonly found in rear-wheel-drive vehicles, where they transmit power from the transmission to the rear axle. They are also used in industrial machinery, such as pumps, generators, and conveyors, where a straight and rigid power transmission is required.

2. Tubular Shaft:

Tubular shafts, also called hollow shafts, are drive shafts with a cylindrical tube-like structure. They are constructed with a hollow core and are typically lighter than solid shafts. Tubular shafts offer benefits such as reduced weight, improved torsional stiffness, and better damping of vibrations. They find applications in various vehicles, including cars, trucks, and motorcycles, as well as in industrial equipment and machinery. Tubular drive shafts are commonly used in front-wheel-drive vehicles, where they connect the transmission to the front wheels.

3. Constant Velocity (CV) Shaft:

Constant Velocity (CV) shafts are specifically designed to handle angular movement and maintain a constant velocity between the engine/transmission and the driven components. They incorporate CV joints at both ends, which allow flexibility and compensation for changes in angle. CV shafts are commonly used in front-wheel-drive and all-wheel-drive vehicles, as well as in off-road vehicles and certain heavy machinery. The CV joints enable smooth power transmission even when the wheels are turned or the suspension moves, reducing vibrations and improving overall performance.

4. Slip Joint Shaft:

Slip joint shafts, also known as telescopic shafts, consist of two or more tubular sections that can slide in and out of each other. This design allows for length adjustment, accommodating changes in distance between the engine/transmission and the driven components. Slip joint shafts are commonly used in vehicles with long wheelbases or adjustable suspension systems, such as some trucks, buses, and recreational vehicles. By providing flexibility in length, slip joint shafts ensure a constant power transfer, even when the vehicle chassis experiences movement or changes in suspension geometry.

5. Double Cardan Shaft:

A double Cardan shaft, also referred to as a double universal joint shaft, is a type of drive shaft that incorporates two universal joints. This configuration helps to reduce vibrations and minimize the operating angles of the joints, resulting in smoother power transmission. Double Cardan shafts are commonly used in heavy-duty applications, such as trucks, off-road vehicles, and agricultural machinery. They are particularly suitable for applications with high torque requirements and large operating angles, providing enhanced durability and performance.

6. Composite Shaft:

Composite shafts are made from composite materials such as carbon fiber or fiberglass, offering advantages such as reduced weight, improved strength, and resistance to corrosion. Composite drive shafts are increasingly being used in high-performance vehicles, sports cars, and racing applications, where weight reduction and enhanced power-to-weight ratio are critical. The composite construction allows for precise tuning of stiffness and damping characteristics, resulting in improved vehicle dynamics and drivetrain efficiency.

7. PTO Shaft:

Power Take-Off (PTO) shafts are specialized drive shafts used in agricultural machinery and certain industrial equipment. They are designed to transfer power from the engine or power source to various attachments, such as mowers, balers, or pumps. PTO shafts typically have a splined connection at one end to connect to the power source and a universal joint at the other end to accommodate angular movement. They are characterized by their ability to transmit high torque levels and their compatibility with a range of driven implements.

8. Marine Shaft:

Marine shafts, also known as propeller shafts or tail shafts, are specifically designed for marine vessels. They transmit power from the engine to the propeller, enabling propulsion. Marine shafts are usually long and operate in a harsh environment, exposed to water, corrosion, and high torque loads. They are typically made of stainless steel or other corrosion-resistant materials and are designed to withstand the challenging conditions encountered in marine applications.

It’simportant to note that the specific applications of drive shafts may vary depending on the vehicle or equipment manufacturer, as well as the specific design and engineering requirements. The examples provided above highlight common applications for each type of drive shaft, but there may be additional variations and specialized designs based on specific industry needs and technological advancements.

editor by CX 2024-05-03

China high quality CNC Machining Turning Parts CHINAMFG Voxy Drive Shaft

Product Description

Company Profile

HangZhou HangZhou, which is a manufacturer specializing in the machining parts with rich manufacturing and design experience for 20 years.

Our products include: gringing parts, machining parts, turning parts, lathe parts, milling parts, CNC milling parts, CNC machining parts, CNC turning parts, CNC lathe parts, CNC metal parts, casting and forging parts, assembly service, laser cutting parts, flange and fitting, die casting parts, metal stamping parts, gear and transmission, aluminum profile, automation group, shaft parts, embedded nut and all kinds of custom/customize parts.

Welcome to send us your drawing for CNC parts machining service, we can customize as your request.

Product Parameters

| 1.Material | Brass, Red Copper, Bronze, Carbon Steel, Stainless Steel, Aluminium |

| 2.Tolerance | +/-0.005mm |

| 3.Finishing | anodizing,polishing,plating ,blacken ect |

| 4.Surfaces | free of scratches |

| 5. Various materials and finishing ways are available | |

| 6. Material and finishing comply with RoHS Directive | |

| 7. Small orders are welcome | |

Equipment List

| Name | Origin | Precision |

| CNC machining center | Japan | 0.005mm |

| Tsugami & Star CNC | Japan | 0.005mm |

| Grinding machine | ZheJiang | 0.002mm |

| Milling machine | Japan | 0.01mm |

| Turn-mill combination machine | Japan | 0.005mm |

| Wire drawing machine | ZheJiang | 0.02mm |

Inspection Equipment

Profilometer, Pneumatic micrometer, Roughness tester

Product Application

Electronical accessories, Automotive accesories, Telecommunication accesories, Engineering parts, Medical equipment, 3C electronical accessories.

Material Capability

Brass, Red Copper, Bronze, Stannum

Stainless steel: SUS303, 304, 316L, 17-4, 420F, 430F

Carbon Steel: S45C, 12L14, 12L15, 11SMnPb30

Aluminum: 7075, 6061

FAQ

1.How long and how can I get quotation from your company?

We will reply you in 2 hours if getting detailed information during working days.

In order to quote you as soon as possible, please provide us the following information together with your inquiry.

1). Detailed drawings (CAD/PDF/DWG/IGS/STEP/JPG)

2). Materials required

3). Surface treatment

4). Quantity (per order/per month/annual)

5). Any special demands or requirements, such as packing, labels,delivery,etc.

2.Can I get samples for testing?

We can offer free samples for small parts, but for big and high-value products, samples will be charged.

3.How about the payment terms?

For new customers, we prefer to use T/T in advance. We can accept L/C, D/P for old customers.

4.If I need urgent delivery, can you help?

Of course! Customer first is our company philosophy. You need to tell us the delivery time when placing the order, and we will do our best to adjust the production schedule.

5.How about the transportation?

You can choose any mode of transportation you need, sea delivery, air delivery or express delivery.

6.How about the quality guarantee?

We will make 100% inspection before packing and delivery and make sure the products 100% meet your requirements . If there is any problems during using, please tell us anytime, we will reply you in time

7.Can we CZPT NDA?

Sure. We never divulge any customer’s information to anyone else.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Fastener, Auto and Motorcycle Accessory, Hardware Tool, Machinery Accessory, Medical/Commication/Vehicle, Metal Processing Machinery Parts |

|---|---|

| Standard: | GB, EN, API650, China GB Code, JIS Code, TEMA, ASME, DIN, ASTM, GB, JIS |

| Surface Treatment: | Electroplating, Degrease |

| Samples: |

US$ 0.5/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can drive shafts be adapted for use in both automotive and industrial settings?

Yes, drive shafts can be adapted for use in both automotive and industrial settings. While there may be some differences in design and specifications based on the specific application requirements, the fundamental principles and functions of drive shafts remain applicable in both contexts. Here’s a detailed explanation:

1. Power Transmission:

Drive shafts serve the primary purpose of transmitting rotational power from a power source, such as an engine or motor, to driven components, which can be wheels, machinery, or other mechanical systems. This fundamental function applies to both automotive and industrial settings. Whether it’s delivering power to the wheels of a vehicle or transferring torque to industrial machinery, the basic principle of power transmission remains the same for drive shafts in both contexts.

2. Design Considerations:

While there may be variations in design based on specific applications, the core design considerations for drive shafts are similar in both automotive and industrial settings. Factors such as torque requirements, operating speeds, length, and material selection are taken into account in both cases. Automotive drive shafts are typically designed to accommodate the dynamic nature of vehicle operation, including variations in speed, angles, and suspension movement. Industrial drive shafts, on the other hand, may be designed for specific machinery and equipment, taking into consideration factors such as load capacity, operating conditions, and alignment requirements. However, the underlying principles of ensuring proper dimensions, strength, and balance are essential in both automotive and industrial drive shaft designs.

3. Material Selection:

The material selection for drive shafts is influenced by the specific requirements of the application, whether in automotive or industrial settings. In automotive applications, drive shafts are commonly made from materials such as steel or aluminum alloys, chosen for their strength, durability, and ability to withstand varying operating conditions. In industrial settings, drive shafts may be made from a broader range of materials, including steel, stainless steel, or even specialized alloys, depending on factors such as load capacity, corrosion resistance, or temperature tolerance. The material selection is tailored to meet the specific needs of the application while ensuring efficient power transfer and durability.

4. Joint Configurations:

Both automotive and industrial drive shafts may incorporate various joint configurations to accommodate the specific requirements of the application. Universal joints (U-joints) are commonly used in both contexts to allow for angular movement and compensate for misalignment between the drive shaft and driven components. Constant velocity (CV) joints are also utilized, particularly in automotive drive shafts, to maintain a constant velocity of rotation and accommodate varying operating angles. These joint configurations are adapted and optimized based on the specific needs of automotive or industrial applications.

5. Maintenance and Service:

While maintenance practices may vary between automotive and industrial settings, the importance of regular inspection, lubrication, and balancing remains crucial in both cases. Both automotive and industrial drive shafts benefit from periodic maintenance to ensure optimal performance, identify potential issues, and prolong the lifespan of the drive shafts. Lubrication of joints, inspection for wear or damage, and balancing procedures are common maintenance tasks for drive shafts in both automotive and industrial applications.

6. Customization and Adaptation:

Drive shafts can be customized and adapted to meet the specific requirements of various automotive and industrial applications. Manufacturers often offer drive shafts with different lengths, diameters, and joint configurations to accommodate a wide range of vehicles or machinery. This flexibility allows for the adaptation of drive shafts to suit the specific torque, speed, and dimensional requirements of different applications, whether in automotive or industrial settings.

In summary, drive shafts can be adapted for use in both automotive and industrial settings by considering the specific requirements of each application. While there may be variations in design, materials, joint configurations, and maintenance practices, the fundamental principles of power transmission, design considerations, and customization options remain applicable in both contexts. Drive shafts play a crucial role in both automotive and industrial applications, enabling efficient power transfer and reliable operation in a wide range of mechanical systems.

What safety precautions should be followed when working with drive shafts?

Working with drive shafts requires adherence to specific safety precautions to prevent accidents, injuries, and damage to equipment. Drive shafts are critical components of a vehicle or machinery’s driveline system and can pose hazards if not handled properly. Here’s a detailed explanation of the safety precautions that should be followed when working with drive shafts:

1. Personal Protective Equipment (PPE):

Always wear appropriate personal protective equipment when working with drive shafts. This may include safety goggles, gloves, steel-toed boots, and protective clothing. PPE helps protect against potential injuries from flying debris, sharp edges, or accidental contact with moving parts.

2. Lockout/Tagout Procedures:

Before working on a drive shaft, ensure that the power source is properly locked out and tagged out. This involves isolating the power supply, such as shutting off the engine or disconnecting the electrical power, and securing it with a lockout/tagout device. This prevents accidental engagement of the drive shaft while maintenance or repair work is being performed.

3. Vehicle or Equipment Support:

When working with drive shafts in vehicles or equipment, use proper support mechanisms to prevent unexpected movement. Securely block the vehicle’s wheels or utilize support stands to prevent the vehicle from rolling or shifting during drive shaft removal or installation. This helps maintain stability and reduces the risk of accidents.

4. Proper Lifting Techniques:

When handling heavy drive shafts, use proper lifting techniques to prevent strain or injuries. Lift with the help of a suitable lifting device, such as a hoist or jack, and ensure that the load is evenly distributed and securely attached. Avoid lifting heavy drive shafts manually or with improper lifting equipment, as this can lead to accidents and injuries.

5. Inspection and Maintenance:

Prior to working on a drive shaft, thoroughly inspect it for any signs of damage, wear, or misalignment. If any abnormalities are detected, consult a qualified technician or engineer before proceeding. Regular maintenance is also essential to ensure the drive shaft is in good working condition. Follow the manufacturer’s recommended maintenance schedule and procedures to minimize the risk of failures or malfunctions.

6. Proper Tools and Equipment:

Use appropriate tools and equipment specifically designed for working with drive shafts. Improper tools or makeshift solutions can lead to accidents or damage to the drive shaft. Ensure that tools are in good condition, properly sized, and suitable for the task at hand. Follow the manufacturer’s instructions and guidelines when using specialized tools or equipment.

7. Controlled Release of Stored Energy:

Some drive shafts, particularly those with torsional dampers or other energy-storing components, can store energy even when the power source is disconnected. Exercise caution when working on such drive shafts and ensure that the stored energy is safely released before disassembly or removal.

8. Training and Expertise:

Work on drive shafts should only be performed by individuals with the necessary training, knowledge, and expertise. If you are not familiar with drive shafts or lack the required skills, seek assistance from qualified technicians or professionals. Improper handling or installation of drive shafts can lead to accidents, damage, or compromised performance.

9. Follow Manufacturer’s Guidelines:

Always follow the manufacturer’s guidelines, instructions, and warnings specific to the drive shaft you are working with. These guidelines provide important information regarding installation, maintenance, and safety considerations. Deviating from the manufacturer’s recommendations may result in unsafe conditions or void warranty coverage.

10. Disposal of Old or Damaged Drive Shafts:

Dispose of old or damaged drive shafts in accordance with local regulations and environmental guidelines. Improper disposal can have negative environmental impacts and may violate legal requirements. Consult with local waste management authorities or recycling centers to ensure appropriate disposal methods are followed.

By following these safety precautions, individuals can minimize the risks associated with working with drive shafts and promote a safe working environment. It is crucial to prioritize personal safety, use proper equipment and techniques, and seek professional help when needed to ensure the proper handling and maintenance of drive shafts.

What is a drive shaft and how does it function in vehicles and machinery?

A drive shaft, also known as a propeller shaft or prop shaft, is a mechanical component that plays a critical role in transmitting rotational power from the engine to the wheels or other driven components in vehicles and machinery. It is commonly used in various types of vehicles, including cars, trucks, motorcycles, and agricultural or industrial machinery. Here’s a detailed explanation of what a drive shaft is and how it functions:

1. Definition and Construction: A drive shaft is a cylindrical metal tube that connects the engine or power source to the wheels or driven components. It is typically made of steel or aluminum and consists of one or more tubular sections with universal joints (U-joints) at each end. These U-joints allow for angular movement and compensation of misalignment between the engine/transmission and the driven wheels or components.

2. Power Transmission: The primary function of a drive shaft is to transmit rotational power from the engine or power source to the wheels or driven components. In vehicles, the drive shaft connects the transmission or gearbox output shaft to the differential, which then transfers power to the wheels. In machinery, the drive shaft transfers power from the engine or motor to various driven components such as pumps, generators, or other mechanical systems.

3. Torque and Speed: The drive shaft is responsible for transmitting both torque and rotational speed. Torque is the rotational force generated by the engine or power source, while rotational speed is the number of revolutions per minute (RPM). The drive shaft must be capable of transmitting the required torque without excessive twisting or bending and maintaining the desired rotational speed for efficient operation of the driven components.

4. Flexible Coupling: The U-joints on the drive shaft provide a flexible coupling that allows for angular movement and compensation of misalignment between the engine/transmission and the driven wheels or components. As the suspension system of a vehicle moves or the machinery operates on uneven terrain, the drive shaft can adjust its length and angle to accommodate these movements, ensuring smooth power transmission and preventing damage to the drivetrain components.

5. Length and Balance: The length of the drive shaft is determined by the distance between the engine or power source and the driven wheels or components. It should be appropriately sized to ensure proper power transmission and avoid excessive vibrations or bending. Additionally, the drive shaft is carefully balanced to minimize vibrations and rotational imbalances, which can cause discomfort, reduce efficiency, and lead to premature wear of drivetrain components.

6. Safety Considerations: Drive shafts in vehicles and machinery require proper safety measures. In vehicles, drive shafts are often enclosed within a protective tube or housing to prevent contact with moving parts and reduce the risk of injury in the event of a malfunction or failure. Additionally, safety shields or guards are commonly installed around exposed drive shafts in machinery to protect operators from potential hazards associated with rotating components.

7. Maintenance and Inspection: Regular maintenance and inspection of drive shafts are essential to ensure their proper functioning and longevity. This includes checking for signs of wear, damage, or excessive play in the U-joints, inspecting the drive shaft for any cracks or deformations, and lubricating the U-joints as recommended by the manufacturer. Proper maintenance helps prevent failures, ensures optimal performance, and prolongs the service life of the drive shaft.

In summary, a drive shaft is a mechanical component that transmits rotational power from the engine or power source to the wheels or driven components in vehicles and machinery. It functions by providing a rigid connection between the engine/transmission and the driven wheels or components, while also allowing for angular movement and compensation of misalignment through the use of U-joints. The drive shaft plays a crucial role in power transmission, torque and speed delivery, flexible coupling, length and balance considerations, safety, and maintenance requirements. Its proper functioning is essential for the smooth and efficient operation of vehicles and machinery.

editor by CX 2024-01-19

in Bilaspur India sales price shop near me near me shop factory supplier OEM High Precision CNC Machining Auto Transmission Spline Shaft Parts manufacturer best Cost Custom Cheap wholesaler

Good quality and credit history are the bases that make a corporation alive. We provide OEM service. Thanks to our wide product selection and wealthy ordeals in this market, Functionality amp Benefit:

| EPT | Above 70 sets computerized lathes, more than 30 sets CNC lathes, above 10 sets CNC machining cEPTTr, in excess of 200 sets secondary processing EPTTs. |

|||||

| RFQ | Customer Inquiry #8594EPT EPTT #8594Cost Analysis #8594EPT Analysis #8594Quote to Client raquo 1-3 Function DaEPTTOnly raquo Post RFQ with complete industrial terms |

|||||

| Sample Making | Sample OrEPTT #8594 EPT Evaluation #8594 Sample Plan to Customer #8594 Sample Standing Tracking #8594 Post Samples with Doc. raquo EPT L/T: 2-four wks, Sample L/T: two wks raquo Ongoing Sample Standing Monitoring raquo Complete Documents for sample acceptance |

|||||

| OrEPTTManagement | CRM Method #8594 Open OrEPTTConfirm #8594 EPT Arrangement. raquo Creation L/T: 2-four wks raquo Weekly Open up OrEPTTConfirm raquo Chosen 3PL Support to Buyers |

|||||

| EPTT EPTT | Certificates: RoHS, ISO9001:2008, SGS. IQC #8594 IPQC #8594 OQC/FQC #8594 EPTT Complain Comments #8594 Audit amp Education. raquo Plant Audit and Experienced by planet popular business raquo Stringent EPTT Administration Procedure with Traceability |

|||||

| Software | Aerospace/ Marine/ Metro/ EPTbike/ EPTT EPTT, EPT amp Meters, Workplace equipments, Property EPT, Healthcare equipments, EPTmunication, EPT amp EPTs, Fire detection method, and so forth | |||||

| Advantage | One-Quit Answer for EPT Clients Wealthy expertise in Tiny Quantity amp Large selection Abundant expertise in Big Volume 20 many years area knowledge, and eighty engineers |

| Processing Approach | CNC machining, Turning, Milling, Stamping, Sheet metallic, Assembly |

| EPTs Offered | Stainless steel, EPTT steel, Brass, Bronze, Iron, EPTT alloy, Nylon, SPCC, SECC, and so forth. |

| EPTs stXiHu (West EPT) Dis.Hu (West EPT) Dis.rd | GB, ASTM, EN, DIN, JIS, BS, EPTT, SAE |

| Processing Capability | Out Diameter: .5mm-five hundred.0mm Length: 1.0mm-2000mm |

| Tolerance | plusmn0.005mm |

| Surface Therapy | Anodizing, Sandblast, Electroplating, PowEPTTcoating, Liquid Portray, PVD, Electrolytic poEPTTng, ect. |

Our Potential :

2. EPTT Promise:

three. Manufacturing Method:

4. Our Edge:

five. Software :

Best China manufacturer & factory Custom in Durg-Bhilainagar India OEM custom cnc machining service brass cnc lathe turning parts With high quality best price

There is a technical center of province level, EPG academician working station, experiment station for EPG post doctors, and national 863 program set up in EPG group. With these platforms and strong technical ability, the more than 400 technicians have developed all variety of special high precise and high strength products, conducted mold programs for key components in the car and national industry revitalizing program, resulting more than 5000 developed over, among which 33 items are autonomous patent technology with 4 patent approved .

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Brand Name:

-

OEM

- OEM Service:

-

Support

- Tolerance:

-

0.01-0.05mm or Customized

- Certification:

-

This novel breather plug features a spring that prevents oil bubbles from forming and percolating to the outside.

ISO9001, SGS

- Surface Treatment:

-

Sandblasting,Polishing,Anodize, Zinc,Nickel,Chrome,Plating, etc.

- Application:

-

Automobile,Medical Equipments,Electric Appliance,Hardware,etc.

- Dimension:

-

As Customers’ Request

- The EP Line PTO drive shafts are recognizable because of the EP Line patented coupling mechanism and the flexible cone. The PTO drive shafts are distinguished through user-friendliness, compactness and appealing design. Equipment:

-

Milling/Lathe/Drilling/Four/Three Axis CNC Machining Center

- Drawing Format:

-

PRO/E, Auto CAD, Solid Works,IGS,UG, CAD/CAM/CAE

Supply Ability

- Supply Ability:

- 10000 Piece/Pieces per Month

Packaging & Delivery

- Port

- nb

-

Lead Time

: -

Quantity(Pieces) 1 – 500 >500 Est. Time(days) 30 To be negotiated

Online Customization

Custom OEM custom cnc machining service brass cnc lathe turning parts

Product Description

| Product Type | CNC turning, milling, drilling, grinding, wire EDM cutting etc. |

| Our Services | CNC Machining,Plastic Injection,Stamping,Die Casting,Silicone And Rubber,Aluminum Extrusion,Mould Making,etc |

| Material | Aluminum,Brass,Stainless Steel,Copper,Plastic,Wood,Silicone,Rubber,Or as per the customers’ requirements |

| Surface Treatment |

Anodizing,Sandblasting,Painting,Powder coating,Plating,Silk Printing,Brushing,Polishing,Laser Engraving |

| Dimension | As customers’ request |

| Service Project | To provide production design, production and technical service, mould development and processing, etc |

| Drawing Format: | PRO/E, Auto CAD, Solid Works,IGS,UG, CAD/CAM/CAE |

| Testing Machine | Digital Height Gauge, caliper, Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on |

| Industry used | Machinery; heavy duty equipment; electronic device; Auto spare parts; optical telecommunication |

| Packing | Eco-friendly pp bag / EPE Foam /Carton boxes or wooden boxes As customer’s specific requirements |

| Trial sample time | 7-10 days after confirmation |

| Delivery time | 7-30 days after receive the pre-payments |

| Payment Terms | T/T,Western Union,Paypal |

More service

More Production Part

Surface Treatment

Production Process

Why Us

Best China manufacturer & factory China manufacturer for China professional machining cnc mechanical engineering parts With high quality best price

ensures the stability and consistency of the key function of components.

Overview

Quick Details

- Applicable Industries:

-

ManufacturinSupplied with hollow shaft. Available with cylindrical output shaft.g Plant

- Brand Name:

-

OEM

- OEM Service:

-

Support

- Tolerance:

-

0.01-0.05mm or Customized

- Certification:

-

ISO9001, SGS

- Surface Treatment:

-

Sandblasting,Polishing,Anodize, Zinc,Nickel,Chrome,Plating, etc.

- Application:

-

Automobile,Medical Equipments,Electric Appliance,Hardware,etc.

- Dimension:

-

As Customers’ Request

- Equipment:

-

Milling/Lathe/Drilling/Four/Three Axis CNC Machining Center

Main products include: manure spreading truck, potato planting/harvesting machine, disc plough, disc harrow, grass Mower/slasher, corn and wheat thershers, seeder, mouldboard plow, deep subsoiler machines, rotary tiller, rear blade, fertilizer spreader, combine rice harvester, corn thresher, farm trailer, ridger, trencher, stubble cleaner, earth auger, cultivator and its accessories: Plow disc blades, harrowing film, plough tip and share, cultivator tine, casting parts etc.

- Drawing Format:

-

PRO/E, Auto CAD, Solid Works,IGS,UG, CAD/CAM/CAE

Supply Ability

- Supply Ability:

- 10000 Piece/Pieces per Month

Packaging & Delivery

- Port

- Ningbo, Shanghai

-

Lead Time

: -

Quantity(Bags) 1 – 500 >500 Est. Time(days) 30 To be negotiated

Online Customization

China professional machining cnc mechanical engineering parts

Product Description

| Product Type | CNC turning, milling, drilling, grinding, wire EDM cutting etc. |

| Our SSemi-permanently mounted power take-offs can also be found on industrial and marine engines. These applications typically use a drive shaft and bolted joint to transmit power to a secondary implement or accessory. In the case of a marine application, such shafts may be used to power fire pumps.ervices | CNC Machining,Plastic Injection,Stamping,Die Casting,Silicone And Rubber,Aluminum Extrusion,Mould Making,etc |

| Material | Aluminum,Brass,Stainless Steel,Copper,Plastic,Wood,Silicone,Rubber,Or as per the customers’ requirements |

| Surface Treatment |

Anodizing,Sandblasting,Painting,Powder coating,Plating,Silk Printing,Brushing,Polishing,Laser Engraving |

| Dimension | As customers’ request |

| Service Project | To provide production design, production and technical service, mould development and processing, etc |

| Drawing Format: | PRO/E, Auto CAD, Solid Works,IGS,UG, CAD/CAM/CAE |

| Testing Machine | Digital Height Gauge, caliper, Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on |

| Industry used | Machinery; heavy duty equipment; electronic device; Auto spare parts; optical telecommunication |

| Packing | Eco-friendly pp bag / EPE Foam /Carton boxes or wooden boxes As customer’s specific requirements |

| Trial sample time | 7-10 days after confirmation |

| Delivery time | 7-30 days after receive the pre-payments |

| Payment Terms | T/T,Western Union,Paypal |

OEM Service

OEM Parts

Surface Treatment

Production Process

Why Us

Best China manufacturer & factory wholesale high quality cnc stainless steel precision machining parts With high quality best price

Due to our wide product range and rich experiences in this industry, we are confident to provide our customers flexible and diversified services.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Brand Name:

-

OEM

- OEM Service:

-

Support

- Tolerance:

-

Under the guidance of managerial sense of “Serving agriculture, scoring a success through quality of products and honesty in business”, our products have been trusted by clients and have gained a larger share of market.

0.01-0.05mm or Customized

- Certification:

-

ISO9001, SGS

- Surface Treatment:

-

Sandblasting,Polishing,Anodize, Zinc,Nickel,Chrome,Plating, etc.

- Application:

-

Automobile,Medical Equipments,Electric Appliance,Hardware,etc.

- Dimension:

-

As Customers’ Request

- Equipment:

-

Milling/Lathe/Drilling/Four/Three Axis CNC Machining Center

- Drawing Format:

-

PRO/E, Auto CAD, Solid Works,IGS,UG, CAD/CAM/CAE

Supply Ability

- Supply Ability:

- 10000 Piece/Pieces per Month

Packaging & Delivery

- Port

- nb

-

Lead Time

: -

Quantity(Pieces) 1PTO Shaft A PTO Adapter will be useful when operating Victory’s EMSD and EMHD Embankment Flail mowers. The absence of a PTO Adapter could cause the PTO shaft to conflict with the arm weldment, which connects to the CAT I/II 3 point hitch. – 500 >500 Est. Time(days) 30 To be negotiated

Online Customization

|

Product Name |

wholesale high quality cnc stainless steel precision machining parts |

|

Product Type |

CNC turning, milling, drilling, grinding, wire EDM cutting etc. |

|

Our Services |

CNC Machining,Plastic Injection,Stamping,Die Casting,Silicone And Rubber,Aluminum Extrusion,Mould Making,etc |

|

Material |

Aluminum,Brass,Stainless Steel,Copper,Plastic,Wood,Silicone,Rubber,Or as per the customers’ requirements |

|

Surface Treatment |

Anodizing,Sandblasting,Painting,Powder coating,Plating,Silk Printing,Brushing,Polishing,Laser Engraving |

|

Dimension |

As customers’ request |

|

Service Project |

To provide production design, production and technical service, mould development and processing, etc |

|

Drawing Format |

PRO/E, Auto CAD, Solid Works,IGS,UG, CAD/CAM/CAE |

|

Testing Machine |

Digital Height Gauge, caliper, Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on |

|

Industry used |

Machinery; heavy duty equipment; electronic device; Auto spare parts; optical telecommunication |

|

Packing |

Eco-friendly pp bag / EPE Foam /Carton boxes or wooden boxes |

|

Trial sample time |

7-10 days after confirmation |

|

Delivery time |

7-30 days after receive the pre-payments |

|

Payment Terms |

T/T,Western Union,Paypal |

China High Quality Price Ratio manufacturer for Supply customized OEM precision cnc machining product wholesale aftermarket auto parts

Our product variety involves all kinds of helical equipment, spur gear, bevel gear, equipment rack, worm equipment, sprockets,chains, bearings, pto shaft, agricultural gearboxes.

Overview

Fast Specifics

- Applicable Industries:

-

Manufacturing Plant

- Manufacturer Title:

-

OEM

- OEM Support:

-

Assist

- Tolerance:

-

.01-.05mm or Customized

- Certification:

-

ISO9001, SGS

- Surface Treatment:

-

Sandblasting,Sprucing,Anodize, Zinc,Nickel,Chrome,Plating, and so on.

- Application:

-

Automobile,Medical Equipments,Electric powered Equipment,Hardware,etc.

- Dimension:

-

As Customers’ Ask for

- Equipment:

-

Milling/Lathe/Drilling/4/A few Axis CNC Machining Heart

- Drawing Format:

-

Pro/E, Car CAD, Sound Operates,IGS,UG, CAD/CAM/CAE

Provide Capacity

- Provide Potential:

- 10000 Piece/Parts for every Thirty day period

Packaging & Supply

- Port

- Ningbo, Shanghai

-

Direct Time

: -

Amount(Bags) one – 500 >500 Est. Time(days) 30 To be negotiated

On the internet Customization

Offer custom-made OEM precision cnc machining product wholesale aftermarket car components

Product Description

| Product Type | CNC turning, milling, drilling, grinding, wire EDM chopping and so forth. |

| Our Providers | CNC Machining,Plastic Injection,Stamping,Die Casting,Silicone And Rubber,Aluminum Extrusion,Mould Generating,and so on |

| Material | Aluminum,Brass,Stainless Steel,Copper,Plastic,Wooden,Silicone,Rubber,Or as for each the customers’ needs |

| Surface Remedy |

Anodizing,Sandblasting,Portray,Powder coating,Plating,Silk Printing,Brushing,Sprucing,Laser Engraving |

| Dimension | As customers’ ask for |

| Service Project | To give generation design, creation and technological services, mould development and processing, and so on |

| Drawing Format: | PRO/E, Auto CAD, Solid Performs,IGS,UG, CAD/CAM/CAE |

| Testing Device | Digital Height Gauge, caliper, Coordinate measuring device, projection machine, roughness tester, hardness tester and so on |

| Industry utilised | Machinery heavy obligation gear electronic unit Car spare components optical telecommunication |

| Packing | Eco-helpful pp bag / EPE Foam /Carton packing containers or picket boxes As customer’s particular requirements |

| Trial sample time | 7-10 times soon after confirmation |

| Delivery time | 7-30 times after receive the pre-payments |

| Payment Terms | T/T,Western Union,Paypal |

OEM Services

OEM Parts

Floor Remedy

Creation Approach

Why Us

custom China best factory precision aluminum parts anodizing cnc machining milling parts Flange plate

The item nicely displays environmental defense and power conserving.

Overview

Rapid Details

- Relevant Industries:

-

Producing Plant

- Model Title:

-

OEM

- OEM Support:

-

Help

- Tolerance:

-

.01-.05mm or Custom-made

- Certification:

-

ISO9001, SGS

- Surface area Treatment method:

-

Sandblasting,Sprucing,Anodize, Zinc,Nickel,Chrome,Plating, and so on.

- Application:

-

Car,Healthcare Equipments,Electric Appliance,Hardware,and many others.

- Dimension:

-

As Customers’ Request

- Products:

-

Milling/Lathe/Drilling/4/A few Axis CNC Machining Center

- Drawing Structure:

-

Professional/E, Auto CAD, Reliable Works,IGS,UG, CAD/CAM/CAE

Supply Capability

- Offer Capacity:

- ten thousand Piece/Pieces for every Thirty day period

Packaging & Shipping and delivery

- Port

- nb

-

Guide Time

: -

Amount(Parts) one – 500 >500 Est. Time(days) thirty To be negotiated

Online Customization

|

Solution Title |

customized precision aluminum elements anodizing cnc machining milling areas Flange plate |

|

Merchandise Type |

CNC turning, milling, drilling, grinding, wire EDM reducing and so on. |

|

Our Services |

CNC Machining,Plastic Injection,Stamping,Die Casting,Silicone And Rubber,Aluminum Extrusion,Mould Creating,and many others |

|

Substance |

Aluminum,Brass,Stainless Steel,Copper,Plastic,Wooden,Silicone,Rubber,Or as for each the customers’ specifications |

|

Floor Therapy |

Anodizing,Sandblasting,Painting,Powder coating,Plating,Silk Printing,Brushing,Sprucing,Laser Engraving |

|

Dimension |

As customers’ request |

|

Provider Project |

To supply manufacturing layout, manufacturing and technical service, mould advancement and processing, etc |

|

Drawing Structure |

Pro/E, Automobile CAD, Sound Performs,IGS,UG, CAD/CAM/CAE |

|

Screening Machine |

Digital Height Gauge, caliper, Coordinate measuring equipment, projection machine, roughness tester, hardness tester and so on |

|

Sector employed |

Equipment heavy obligation tools digital device Car spare components optical telecommunication |

|

Packing |

Eco-pleasant pp bag / EPE Foam /Carton boxes or wood packing containers |

|

Demo sample time |

7-ten times after affirmation |

|

Shipping time |

seven-30 times after acquire the pre-payments |

|

Payment Conditions |

T/T,Western Union,Paypal |