Product Description

Product Description

Basic Info.

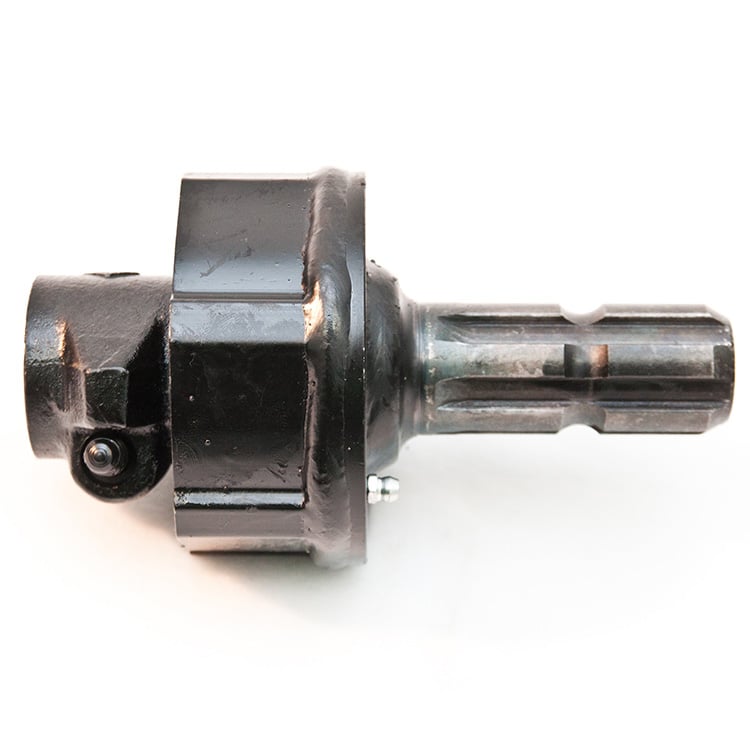

| Model NO. | NH1B | Customize | Avaliable |

| Production Name | Agricultural Machine Use Drive Shaft Connect Machines Pto Truck | Warranty | 1 year |

| Trademark | Yontan | Specification | Customized |

| Origin | ZheJiang , China | Delivery time | 3-7 days |

| Application | for All The Dump Truck | Production capacity | 20000pcs/year |

| Transport Package | Wooden Case | HS Code | 8708994900 |

Product Description

The function of the power take-off is to output power to external work. It is usually composed of a gearbox, a clutch, and a controller. It is 1 or more sets of transmission gears. There are many classifications of power take-offs. Among them, the power output form on the side of the transmission can only output one-half of the maximum power of the engine, while the power output form on the front of the transmission can obtain the maximum power of the engine, so it is called full power output take-off. Powerful weapon.

Company Profile

ZheJiang Yontan Import and Export Co., Ltd. was established in HangZhou, the capital of ZheJiang Province, a famous national historical and cultural city with profound heritage. The company is mainly engaged in the export of complete vehicles of SINOTRUk, HOWO, SHACMAN, FOTON, FAW, XIHU (WEST LAKE) DIS., XIHU (WEST LAKE) DIS.FENG and other brands. It is engaged in the export sales of a full range of truck accessories and assemblies. The products distributed by the company are mainly supplied to major domestic transportation units, oil and gas transportation teams, municipal engineering fleets and civil engineering fleets, as well as major foreign construction companies and transportation companies.

On the basis of the continuous development of the company’s business, we are committed to exploring the international market. So far, our market has covered China, Eastern Europe, the Middle East, Africa, Southeast Asia, South America and other countries and regions. Our integrity is everywhere and we are deeply trusted by customers. Our company has a large warehouse and a professional management team, which can quickly find suitable parts for customers, and can provide services such as good packaging, safe storage, and fast transportation to meet the diverse needs of customers at any time.

FAQ

★ What is your terms of packing?

A: Generally, we pack our goods in neutral white boxes and brown cartons. If you have legally registered patent,

we can pack the goods in your branded boxes after getting your authorization letters.

★ What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We’ll show you the photos of the products and packages

before you pay the balance.

★Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Action now contact us for whole CATALOG.

More than 5000kinds of OEM parts waiting for you. Please contact us!

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Great |

|---|---|

| Warranty: | 1year |

| Certification: | ISO9001 |

| Driving System Parts: | Wheel |

| Electrical System Parts: | Starting System |

| Brake System Parts: | Transmission |

| Samples: |

US$ 30/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Are there any limitations or disadvantages associated with drive shafts?

While drive shafts are widely used and offer several advantages, they also have certain limitations and disadvantages that should be considered. Here’s a detailed explanation of the limitations and disadvantages associated with drive shafts:

1. Length and Misalignment Constraints:

Drive shafts have a maximum practical length due to factors such as material strength, weight considerations, and the need to maintain rigidity and minimize vibrations. Longer drive shafts can be prone to increased bending and torsional deflection, leading to reduced efficiency and potential driveline vibrations. Additionally, drive shafts require proper alignment between the driving and driven components. Misalignment can cause increased wear, vibrations, and premature failure of the drive shaft or its associated components.

2. Limited Operating Angles:

Drive shafts, especially those using U-joints, have limitations on operating angles. U-joints are typically designed to operate within specific angular ranges, and operating beyond these limits can result in reduced efficiency, increased vibrations, and accelerated wear. In applications requiring large operating angles, constant velocity (CV) joints are often used to maintain a constant speed and accommodate greater angles. However, CV joints may introduce higher complexity and cost compared to U-joints.

3. Maintenance Requirements:

Drive shafts require regular maintenance to ensure optimal performance and reliability. This includes periodic inspection, lubrication of joints, and balancing if necessary. Failure to perform routine maintenance can lead to increased wear, vibrations, and potential driveline issues. Maintenance requirements should be considered in terms of time and resources when using drive shafts in various applications.

4. Noise and Vibration:

Drive shafts can generate noise and vibrations, especially at high speeds or when operating at certain resonant frequencies. Imbalances, misalignment, worn joints, or other factors can contribute to increased noise and vibrations. These vibrations may affect the comfort of vehicle occupants, contribute to component fatigue, and require additional measures such as dampers or vibration isolation systems to mitigate their effects.

5. Weight and Space Constraints:

Drive shafts add weight to the overall system, which can be a consideration in weight-sensitive applications, such as automotive or aerospace industries. Additionally, drive shafts require physical space for installation. In compact or tightly packaged equipment or vehicles, accommodating the necessary drive shaft length and clearances can be challenging, requiring careful design and integration considerations.

6. Cost Considerations:

Drive shafts, depending on their design, materials, and manufacturing processes, can involve significant costs. Customized or specialized drive shafts tailored to specific equipment requirements may incur higher expenses. Additionally, incorporating advanced joint configurations, such as CV joints, can add complexity and cost to the drive shaft system.

7. Inherent Power Loss:

Drive shafts transmit power from the driving source to the driven components, but they also introduce some inherent power loss due to friction, bending, and other factors. This power loss can reduce overall system efficiency, particularly in long drive shafts or applications with high torque requirements. It is important to consider power loss when determining the appropriate drive shaft design and specifications.

8. Limited Torque Capacity:

While drive shafts can handle a wide range of torque loads, there are limits to their torque capacity. Exceeding the maximum torque capacity of a drive shaft can lead to premature failure, resulting in downtime and potential damage to other driveline components. It is crucial to select a drive shaft with sufficient torque capacity for the intended application.

Despite these limitations and disadvantages, drive shafts remain a widely used and effective means of power transmission in various industries. Manufacturers continuously work to address these limitations through advancements in materials, design techniques, joint configurations, and balancing processes. By carefully considering the specific application requirements and potential drawbacks, engineers and designers can mitigate the limitations and maximize the benefits of drive shafts in their respective systems.

Can drive shafts be customized for specific vehicle or equipment requirements?

Yes, drive shafts can be customized to meet specific vehicle or equipment requirements. Customization allows manufacturers to tailor the design, dimensions, materials, and other parameters of the drive shaft to ensure compatibility and optimal performance within a particular vehicle or equipment. Here’s a detailed explanation of how drive shafts can be customized:

1. Dimensional Customization:

Drive shafts can be customized to match the dimensional requirements of the vehicle or equipment. This includes adjusting the overall length, diameter, and spline configuration to ensure proper fitment and clearances within the specific application. By customizing the dimensions, the drive shaft can be seamlessly integrated into the driveline system without any interference or limitations.

2. Material Selection:

The choice of materials for drive shafts can be customized based on the specific requirements of the vehicle or equipment. Different materials, such as steel alloys, aluminum alloys, or specialized composites, can be selected to optimize strength, weight, and durability. The material selection can be tailored to meet the torque, speed, and operating conditions of the application, ensuring the drive shaft’s reliability and longevity.

3. Joint Configuration:

Drive shafts can be customized with different joint configurations to accommodate specific vehicle or equipment requirements. For example, universal joints (U-joints) may be suitable for applications with lower operating angles and moderate torque demands, while constant velocity (CV) joints are often used in applications requiring higher operating angles and smoother power transmission. The choice of joint configuration depends on factors such as operating angle, torque capacity, and desired performance characteristics.

4. Torque and Power Capacity:

Customization allows drive shafts to be designed with the appropriate torque and power capacity for the specific vehicle or equipment. Manufacturers can analyze the torque requirements, operating conditions, and safety margins of the application to determine the optimal torque rating and power capacity of the drive shaft. This ensures that the drive shaft can handle the required loads without experiencing premature failure or performance issues.

5. Balancing and Vibration Control:

Drive shafts can be customized with precision balancing and vibration control measures. Imbalances in the drive shaft can lead to vibrations, increased wear, and potential driveline issues. By employing dynamic balancing techniques during the manufacturing process, manufacturers can minimize vibrations and ensure smooth operation. Additionally, vibration dampers or isolation systems can be integrated into the drive shaft design to further mitigate vibrations and enhance overall system performance.

6. Integration and Mounting Considerations:

Customization of drive shafts takes into account the integration and mounting requirements of the specific vehicle or equipment. Manufacturers work closely with the vehicle or equipment designers to ensure that the drive shaft fits seamlessly into the driveline system. This includes adapting the mounting points, interfaces, and clearances to ensure proper alignment and installation of the drive shaft within the vehicle or equipment.

7. Collaboration and Feedback:

Manufacturers often collaborate with vehicle manufacturers, OEMs (Original Equipment Manufacturers), or end-users to gather feedback and incorporate their specific requirements into the drive shaft customization process. By actively seeking input and feedback, manufacturers can address specific needs, optimize performance, and ensure compatibility with the vehicle or equipment. This collaborative approach enhances the customization process and results in drive shafts that meet the exact requirements of the application.

8. Compliance with Standards:

Customized drive shafts can be designed to comply with relevant industry standards and regulations. Compliance with standards, such as ISO (International Organization for Standardization) or specific industry standards, ensures that the customized drive shafts meet quality, safety, and performance requirements. Adhering to these standards provides assurance that the drive shafts are compatible and can be seamlessly integrated into the specific vehicle or equipment.

In summary, drive shafts can be customized to meet specific vehicle or equipment requirements through dimensional customization, material selection, joint configuration, torque and power capacity optimization, balancing and vibration control, integration and mounting considerations, collaboration with stakeholders, and compliance with industry standards. Customization allows drive shafts to be precisely tailored to the needs of the application, ensuring compatibility, reliability, and optimal performance.

How do drive shafts handle variations in length and torque requirements?

Drive shafts are designed to handle variations in length and torque requirements in order to efficiently transmit rotational power. Here’s an explanation of how drive shafts address these variations:

Length Variations:

Drive shafts are available in different lengths to accommodate varying distances between the engine or power source and the driven components. They can be custom-made or purchased in standardized lengths, depending on the specific application. In situations where the distance between the engine and the driven components is longer, multiple drive shafts with appropriate couplings or universal joints can be used to bridge the gap. These additional drive shafts effectively extend the overall length of the power transmission system.

Additionally, some drive shafts are designed with telescopic sections. These sections can be extended or retracted, allowing for adjustments in length to accommodate different vehicle configurations or dynamic movements. Telescopic drive shafts are commonly used in applications where the distance between the engine and the driven components may change, such as in certain types of trucks, buses, and off-road vehicles.

Torque Requirements:

Drive shafts are engineered to handle varying torque requirements based on the power output of the engine or power source and the demands of the driven components. The torque transmitted through the drive shaft depends on factors such as the engine power, load conditions, and the resistance encountered by the driven components.

Manufacturers consider torque requirements when selecting the appropriate materials and dimensions for drive shafts. Drive shafts are typically made from high-strength materials, such as steel or aluminum alloys, to withstand the torque loads without deformation or failure. The diameter, wall thickness, and design of the drive shaft are carefully calculated to ensure it can handle the expected torque without excessive deflection or vibration.

In applications with high torque demands, such as heavy-duty trucks, industrial machinery, or performance vehicles, drive shafts may have additional reinforcements. These reinforcements can include thicker walls, cross-sectional shapes optimized for strength, or composite materials with superior torque-handling capabilities.

Furthermore, drive shafts often incorporate flexible joints, such as universal joints or constant velocity (CV) joints. These joints allow for angular misalignment and compensate for variations in the operating angles between the engine, transmission, and driven components. They also help absorb vibrations and shocks, reducing stress on the drive shaft and enhancing its torque-handling capacity.

In summary, drive shafts handle variations in length and torque requirements through customizable lengths, telescopic sections, appropriate materials and dimensions, and the inclusion of flexible joints. By carefully considering these factors, drive shafts can efficiently and reliably transmit power while accommodating the specific needs of different applications.

editor by CX 2024-05-06

China Custom Ring Gear Pto Drive Shaft for Agricultural Machine Tractor Parts

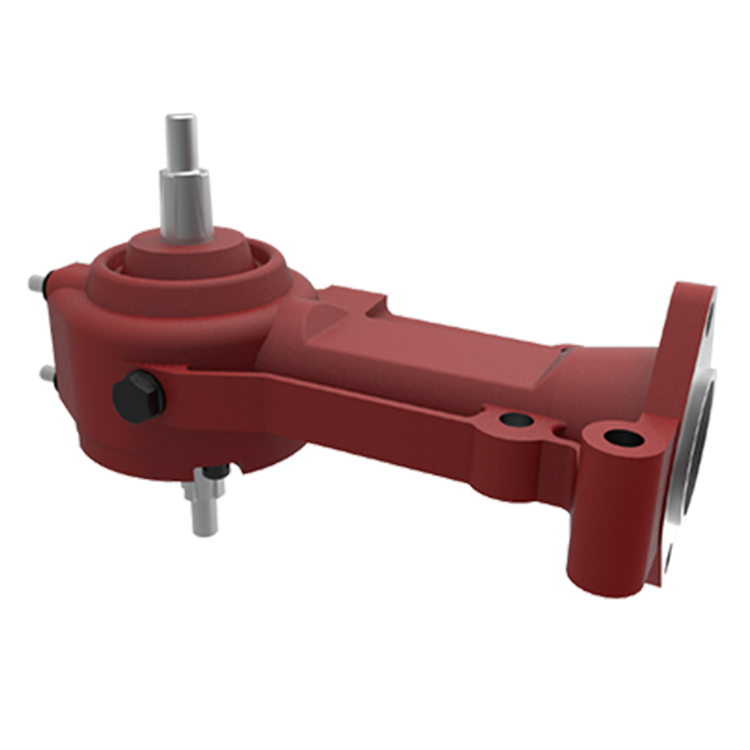

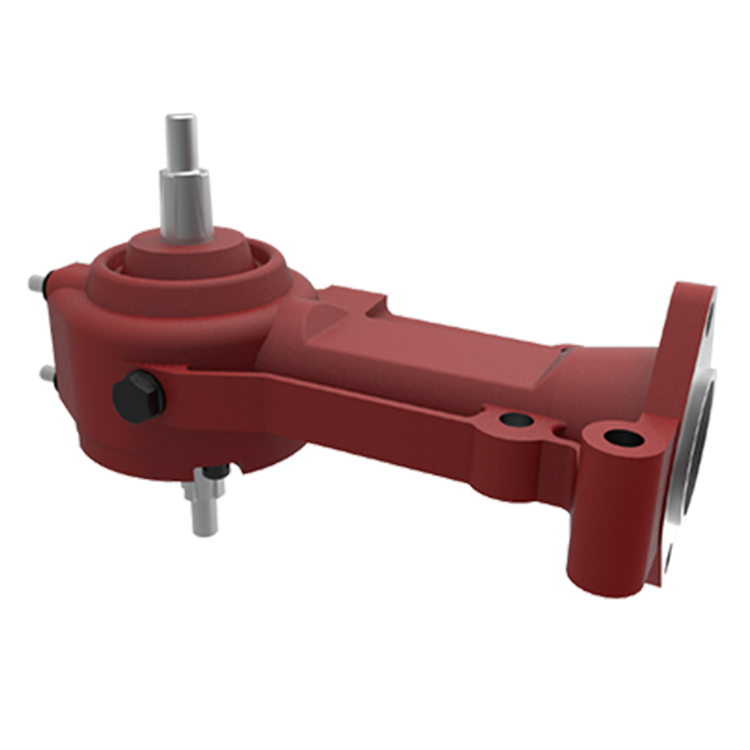

Product Description

Product Range: Tractor And Harvester Gear For John Deere

Application : Agricultural Farm Tractor gearbox

OEM Number: Unknown

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Pinion Gear |

|---|---|

| Usage: | Farmland Infrastructure, Tillage, Harvester, Tractor Spare Parts |

| Material: | 20crmnti/45/40cr |

| Samples: |

US$ 500/Piece

1 Piece(Min.Order) | Order Sample It could be served as deposit

|

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What maintenance practices are crucial for prolonging the lifespan of drive shafts?

To prolong the lifespan of drive shafts and ensure their optimal performance, several maintenance practices are crucial. Regular maintenance helps identify and address potential issues before they escalate, reduces wear and tear, and ensures the drive shaft operates smoothly and efficiently. Here are some essential maintenance practices for prolonging the lifespan of drive shafts:

1. Regular Inspection:

Performing regular inspections is vital for detecting any signs of wear, damage, or misalignment. Inspect the drive shaft visually, looking for cracks, dents, or any signs of excessive wear on the shaft itself and its associated components such as joints, yokes, and splines. Check for any signs of lubrication leaks or contamination. Additionally, inspect the fasteners and mounting points to ensure they are secure. Early detection of any issues allows for timely repairs or replacements, preventing further damage to the drive shaft.

2. Lubrication:

Proper lubrication is essential for the smooth operation and longevity of drive shafts. Lubricate the joints, such as universal joints or constant velocity joints, as recommended by the manufacturer. Lubrication reduces friction, minimizes wear, and helps dissipate heat generated during operation. Use the appropriate lubricant specified for the specific drive shaft and application, considering factors such as temperature, load, and operating conditions. Regularly check the lubrication levels and replenish as necessary to ensure optimal performance and prevent premature failure.

3. Balancing and Alignment:

Maintaining proper balancing and alignment is crucial for the lifespan of drive shafts. Imbalances or misalignments can lead to vibrations, accelerated wear, and potential failure. If vibrations or unusual noises are detected during operation, it is important to address them promptly. Perform balancing procedures as necessary, including dynamic balancing, to ensure even weight distribution along the drive shaft. Additionally, verify that the drive shaft is correctly aligned with the engine or power source and the driven components. Misalignment can cause excessive stress on the drive shaft, leading to premature failure.

4. Protective Coatings:

Applying protective coatings can help prolong the lifespan of drive shafts, particularly in applications exposed to harsh environments or corrosive substances. Consider using coatings such as zinc plating, powder coating, or specialized corrosion-resistant coatings to enhance the drive shaft’s resistance to corrosion, rust, and chemical damage. Regularly inspect the coating for any signs of degradation or damage, and reapply or repair as necessary to maintain the protective barrier.

5. Torque and Fastener Checks:

Ensure that the drive shaft’s fasteners, such as bolts, nuts, or clamps, are properly torqued and secured according to the manufacturer’s specifications. Loose or improperly tightened fasteners can lead to excessive vibrations, misalignment, or even detachment of the drive shaft. Periodically check and retighten the fasteners as recommended or after any maintenance or repair procedures. Additionally, monitor the torque levels during operation to ensure they remain within the specified range, as excessive torque can strain the drive shaft and lead to premature failure.

6. Environmental Protection:

Protecting the drive shaft from environmental factors can significantly extend its lifespan. In applications exposed to extreme temperatures, moisture, chemicals, or abrasive substances, take appropriate measures to shield the drive shaft. This may include using protective covers, seals, or guards to prevent contaminants from entering and causing damage. Regular cleaning of the drive shaft, especially in dirty or corrosive environments, can also help remove debris and prevent buildup that could compromise its performance and longevity.

7. Manufacturer Guidelines:

Follow the manufacturer’s guidelines and recommendations for maintenance practices specific to the drive shaft model and application. The manufacturer’s instructions may include specific intervals for inspections, lubrication, balancing, or other maintenance tasks. Adhering to these guidelines ensures that the drive shaft is properly maintained and serviced, maximizing its lifespan and minimizing the risk of unexpected failures.

By implementing these maintenance practices, drive shafts can operate reliably, maintain efficient power transmission, and have an extended service life, ultimately reducing downtime and ensuring optimal performance in various applications.

Can you provide real-world examples of vehicles and machinery that use drive shafts?

Drive shafts are widely used in various vehicles and machinery to transmit power from the engine or power source to the wheels or driven components. Here are some real-world examples of vehicles and machinery that utilize drive shafts:

1. Automobiles:

Drive shafts are commonly found in automobiles, especially those with rear-wheel drive or four-wheel drive systems. In these vehicles, the drive shaft transfers power from the transmission or transfer case to the rear differential or front differential, respectively. This allows the engine’s power to be distributed to the wheels, propelling the vehicle forward.

2. Trucks and Commercial Vehicles:

Drive shafts are essential components in trucks and commercial vehicles. They are used to transfer power from the transmission or transfer case to the rear axle or multiple axles in the case of heavy-duty trucks. Drive shafts in commercial vehicles are designed to handle higher torque loads and are often larger and more robust than those used in passenger cars.

3. Construction and Earthmoving Equipment:

Various types of construction and earthmoving equipment, such as excavators, loaders, bulldozers, and graders, rely on drive shafts for power transmission. These machines typically have complex drivetrain systems that use drive shafts to transfer power from the engine to the wheels or tracks, enabling them to perform heavy-duty tasks on construction sites or in mining operations.

4. Agricultural Machinery:

Agricultural machinery, including tractors, combines, and harvesters, utilize drive shafts to transmit power from the engine to the wheels or driven components. Drive shafts in agricultural machinery are often subjected to demanding conditions and may have additional features such as telescopic sections to accommodate variable distances between components.

5. Industrial Machinery:

Industrial machinery, such as manufacturing equipment, generators, pumps, and compressors, often incorporate drive shafts in their power transmission systems. These drive shafts transfer power from electric motors, engines, or other power sources to various driven components, enabling the machinery to perform specific tasks in industrial settings.

6. Marine Vessels:

In marine applications, drive shafts are commonly used to transmit power from the engine to the propeller in boats, ships, and other watercraft. Marine drive shafts are typically longer and designed to withstand the unique challenges posed by water environments, including corrosion resistance and appropriate sealing mechanisms.

7. Recreational Vehicles (RVs) and Motorhomes:

RVs and motorhomes often employ drive shafts as part of their drivetrain systems. These drive shafts transfer power from the transmission to the rear axle, allowing the vehicle to move and providing propulsion. Drive shafts in RVs may have additional features such as dampers or vibration-reducing components to enhance comfort during travel.

8. Off-Road and Racing Vehicles:

Off-road vehicles, such as SUVs, trucks, and all-terrain vehicles (ATVs), as well as racing vehicles, frequently utilize drive shafts. These drive shafts are designed to withstand the rigors of off-road conditions or high-performance racing, transmitting power efficiently to the wheels and ensuring optimal traction and performance.

9. Railway Rolling Stock:

In railway systems, drive shafts are employed in locomotives and some types of rolling stock. They transfer power from the locomotive’s engine to the wheels or propulsion system, enabling the train to move along the tracks. Railway drive shafts are typically much longer and may have additional features to accommodate the articulated or flexible nature of some train configurations.

10. Wind Turbines:

Large-scale wind turbines used for generating electricity incorporate drive shafts in their power transmission systems. The drive shafts transfer rotational energy from the turbine’s blades to the generator, where it is converted into electrical power. Drive shafts in wind turbines are designed to handle the significant torque and rotational forces generated by the wind.

These examples demonstrate the broad range of vehicles and machinery that rely on drive shafts for efficient power transmission and propulsion. Drive shafts are essential components in various industries, enabling the transfer of power from the source to the driven components, ultimately facilitating movement, operation, or the performance of specific tasks.

What benefits do drive shafts offer for different types of vehicles and equipment?

Drive shafts offer several benefits for different types of vehicles and equipment. They play a crucial role in power transmission and contribute to the overall performance, efficiency, and functionality of various systems. Here’s a detailed explanation of the benefits that drive shafts provide:

1. Efficient Power Transmission:

Drive shafts enable efficient power transmission from the engine or power source to the wheels or driven components. By connecting the engine or motor to the driven system, drive shafts efficiently transfer rotational power, allowing vehicles and equipment to perform their intended functions. This efficient power transmission ensures that the power generated by the engine is effectively utilized, optimizing the overall performance and productivity of the system.

2. Versatility:

Drive shafts offer versatility in their applications. They are used in various types of vehicles, including cars, trucks, motorcycles, and off-road vehicles. Additionally, drive shafts are employed in a wide range of equipment and machinery, such as agricultural machinery, construction equipment, industrial machinery, and marine vessels. The ability to adapt to different types of vehicles and equipment makes drive shafts a versatile component for power transmission.

3. Torque Handling:

Drive shafts are designed to handle high levels of torque. Torque is the rotational force generated by the engine or power source. Drive shafts are engineered to efficiently transmit this torque without excessive twisting or bending. By effectively handling torque, drive shafts ensure that the power generated by the engine is reliably transferred to the wheels or driven components, enabling vehicles and equipment to overcome resistance, such as heavy loads or challenging terrains.

4. Flexibility and Compensation:

Drive shafts provide flexibility and compensation for angular movement and misalignment. In vehicles, drive shafts accommodate the movement of the suspension system, allowing the wheels to move up and down independently. This flexibility ensures a constant power transfer even when the vehicle encounters uneven terrain. Similarly, in machinery, drive shafts compensate for misalignment between the engine or motor and the driven components, ensuring smooth power transmission and preventing excessive stress on the drivetrain.

5. Weight Reduction:

Drive shafts contribute to weight reduction in vehicles and equipment. Compared to other forms of power transmission, such as belt drives or chain drives, drive shafts are typically lighter in weight. This reduction in weight helps improve fuel efficiency in vehicles and reduces the overall weight of equipment, leading to enhanced maneuverability and increased payload capacity. Additionally, lighter drive shafts contribute to a better power-to-weight ratio, resulting in improved performance and acceleration.

6. Durability and Longevity:

Drive shafts are designed to be durable and long-lasting. They are constructed using materials such as steel or aluminum, which offer high strength and resistance to wear and fatigue. Drive shafts undergo rigorous testing and quality control measures to ensure their reliability and longevity. Proper maintenance, including lubrication and regular inspections, further enhances their durability. The robust construction and long lifespan of drive shafts contribute to the overall reliability and cost-effectiveness of vehicles and equipment.

7. Safety:

Drive shafts incorporate safety features to protect operators and bystanders. In vehicles, drive shafts are often enclosed within a protective tube or housing, preventing contact with moving parts and reducing the risk of injury in the event of a failure. Similarly, in machinery, safety shields or guards are commonly installed around exposed drive shafts to minimize the potential hazards associated with rotating components. These safety measures ensure the well-being of individuals operating or working in proximity to vehicles and equipment.

In summary, drive shafts offer several benefits for different types of vehicles and equipment. They enable efficient power transmission, provide versatility in various applications, handle torque effectively, offer flexibility and compensation, contribute to weight reduction, ensure durability and longevity, and incorporate safety features. By providing these advantages, drive shafts enhance the performance, efficiency, reliability, and safety of vehicles and equipment across a wide range of industries.

editor by CX 2024-02-19

Best Custom made in China – replacement parts – PTO shaft manufacturer & factory Agricultural 8n pto shaft Spraying Implement Self Propelled Locust Boom Sprayer Machine with ce certificate top quality low price

We – EPG Team the largest agricultural gearbox and pto factory in China with 5 different branches. For much more information: Cellular/whatsapp/telegram/Kakao us at: 0086-13083988828

replacement pto shafts Our new holland pto shaft products woods driveshaft are bolt on pto shaft offering square pto shaft tubing effectively pto locking collar in kubota g1900 pto shaft Chinese 8n ford tractor pto shaft measurement marketplaces braber tools common-purpose pto shaft assembly and pto shaft set up some merchandise sold in intercontinental marketplaces are properly received by Chinese and foreign customers at house and overseas. EPG model rotocultivator ploughshares in T. line ended up chosen as the Nationwide Rotary Tillage Equipment Industry “Best Brand name Goods” in 2007 by Rotocultivator Branch of China Agricultural Machinery Market Association.

3WPZ-1200G kind self propelled spray boom sprayer

3WPZ-1200G collection of sprayer is appropriate for spraying the medicament for the planter of bean, corn, cotton, grain.

Also for lawn,fruiter,vegetable, road side tree. The capability could be 1200L, the spraying width could be 16m with 53hp.

Rewards:

•This variety of increase sprayer is a tractor mounted sprayer.

•Wide doing work scope,spraying for bean,cotton,corn and many others.

•Wide spraying with to be 16m max.and the working angle of this tractor sprayer could be adjusted.

•The capability of mounted boom sprayer could be adjusted to satisfy various need to have from the user.

| Model | 3WPZ-1200G self-propelled spray increase sprayer | Pump Sort | Plunger pump |

| Engine Product | 4L68 (Changchai) turbocharged EPT motor | Pump Design | OS-5200 |

| Power / Speed | 53 hp 2400r / min | Pump Force | 0-45kgf/cm² |

| Displacement Level | China III | Pump Circulation | 220-240L / Min |

| Gear | Forward gear 4,reverse gear 1 | Pump Speed | 600-800r / min |

| Drive Mode | Four-wheel travel | Tank Capability | 1500L |

| Steering Manner | Hydraulic steering | Spray Peak | 0.5-3. m |

| Mixing Strategy | Circulating drinking water mixing | Nozzle Design | No.3 |

| Folding Method | Hydraulic folding | Spray Angle | 110° |

| Spray Width | 16 m | Nozzle Flow | 1.2L / min |

| Ground clearance | 1.8 m(customizable) | System Perform Pressure | 0.3-.5Mpa |

| Wheel Observe | 1.95-2.6 m(adjustable) | 3 Filtration Technique | Tank inlet, pump inlet, nozzle |

| Operating Performance | 21-30 acres / hour | Battery | 12v / 120AH |

| Walking Pace | ≤25Km / h | Front Tire Model | Tractor tires 9.5-24 |

| Overall Dimension | 5800 mm x 2900 mm x 3700 mm | Rear Tire Design | Tractor tires 9.5-24 |

| Weight | 3811Kg | Water Tank | 15L |

Q:Are you a factory or trading firm?

A:We are a factory.

Q: How does your manufacturing unit do with regards to good quality handle?

A: Quality is precedence. we often say great relevance to top quality managing from the extremely beginning to the really end.

Q: Do you have a solution accent?

A: Yes, we have the equipment of the item.

Q:Can you customize the item?

A:We can personalize the product.

Q: What’s your payment terms?

A: Payment terms is T/T or L/C,We accept all reasonable payment.

Q: How about delivery time of your machine?

A: The delivery time is in 60 working days. It depending your quantity.

Best China manufacturer & factory Customized in Bamako Mali Power transmission Yellow Agricultural Transmission Machine PTO Shaft With high quality best price

With EPG manufacturer registered in much more than 70 nations around the world like The usa , Europe , Japan and so on, it has associates among entire world prime enterprises, this sort of as JOHNDEERE, NEW HOLLAND, CLAAS, HONDA, KUBOTA, YANMAR, etc.

Overview

Fast Details

- Warranty:

-

1.5 many years

- Relevant Industries:

-

Producing Plant

- Following Guarantee Support:

-

On-line assist

- Regional Service Location:

-

none

- Showroom Spot:

-

ITALY

- Sort:

-

Shafts

- Place of Origin:Zhejiang, China

- Brand Title:

-

OEM

- Regional Support Spot:

-

Italy

- certificate:

-

CE

- Material:

-

Metal

- Colour:

-

Yellow&Black

- Processing of yoke:

-

Forging

- Processing of tube:

-

Cold drawn

- Layout:

-

Customized

- Certification:

-

CE Certification

Source Ability

- Provide Potential:

- 20000 Piece/Items per Month

Packaging & Shipping

- Packaging Information

- Iron crates

- Port

- NINGBO OR SHANGHAI

On the internet Customization

Solution Information

Product Information

PTO Shaft

The electricity get-off (PTO)Semi-completely mounted energy consider-offs can also be found on industrial and marine engines. These apps normally use a travel shaft and bolted joint to transmit electrical power to a secondary put into action or accent. In the case of a maritime application, this kind of shafts could be utilized to electricity fireplace pumps. is a innovative mechanism, enabling implementIt is our aim to offer a large variety of good quality products at affordable prices, give the very best services for consumers satisfied and lead to our ongoing enhancement. s to draw energy from the motor and transmit it to an additional application. It functions as a mechanical gearbox which can be mounted on the vehicle’s transmission.

The electricity take-off shaft (PTO shaft) is a crucial component, developed and manufactured for constant large-obligation use. A excellent PTO shaft should be sturdy adequate to bear the torsion and shear pressure and reduce vibration.

Setforge, the forging subsidiary of Ever-Electrical power Team, manufactures chilly extruded PTO shafts for all types of agriculture vehicles. Our PTO shafts offer you fantastic dependability and durability in the course of everyday use.

EP Group has been internationally identified as a trustworthy worldwide supplier. Our state-of-the-artwork producing process and skilled engineers ensure the prime-top quality of all Farinia parts.

| After Guarantee Service | Movie specialized assistance |

| Applicable Industries | Manufacturing Plant |

| Neighborhood Support Place | Italy |

| Showroom Location | Italy |

| Guarantee | 1.5 years |

| Variety | Shafts |

| Area of Origin | China |

| Manufacturer Identify | EPG |

| certificate | CE |

| Content | Metal |

| Colour | Yellow&Black |

| Processing of yoke | Forging |

| Processing of tube | Chilly drawn |

| Layout | CusWith its other characteristics, as NITRILE-BUTADIENE rubber ring seals ñ according to DIN 3760 regulation -, substantial good quality bearings, and an aluminium end, this item is the very best option within this productís family members in the gears market.tomized |

| Certificate | CE Certificate |

Product Screen

Product Exhibit

Skid Steer Mount B …

eighteen” Weighty Responsibility Ear …

15″ Rock Auger

CompanyInfo

Organization Profile

Ever-Electricity Group

EPG have large-tech machinery and take a look at products. We can create world class large precision products.

Certifications

Certifications

Cargo & Payment

Our Advantages

A: Your inquiry connected to our merchandise or rates will be replied in 24 hours.

B: Protection of your product sales location, ideas of design and all your non-public information.

C: Very best good quality and competitive price.

……

faq

FAQ

1) How can I place buy?

A: You can speak to us by electronic mail about your get information, or place order on line.

2) How can I pay out you?

A: After you verify our PI, we will ask for you to pay. T/T (HSBC lender) and Paypal, Western Union are the most typical methods we are making use of.

……

Best China manufacturer & factory Implement Machine PTO Agricultural Shaft With high quality best price

Keeping in mind that good service is the key to cooperating with clients, we strive to meet high quality standards, offer competitive prices and ensure prompt delivery.

Overview

Quick Details

- Warranty:

-

1.5 years

- Applicable Industries:

-

Manufacturing Plant

- After Warranty Service:

-

Online support

- Local Service Location:

-

none, Italy

- Showroom Location:

-

ITALY

- Type:

-

Shafts

Breathers or vent plugs eliminate internal pressure buildup, but often provide a leakage path for lubricant. Bubbles of oil form over the air passageway and eventually percolate to the outside.

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- certificate:

-

CE

- Material:

-

Metal

- Color:

-

Yellow&Black

- Processing of yoke:

-

Forging

- Processing of tube:

-

Cold drawn

- Design:

-

Customized

- Certificate:

-

CE Certificate

Our products is popular exported to the United States, Germany, Australia, Russia, Spain, Hungary, Zimbabwe, Ukraine, Nigeria, Peru, Brazil, Middle and South America, Thailand, Pakistan, Indonesia, more than 60 countries and regions.

Supply Ability

- Supply Ability:

- 20000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- Iron crates

- Port

- NINGBO OR SHANGHAI

Online Customization

Adding a second engine simply is not practical, which makes power take off (PTO) a valuable element in providing power to secondary functions. To recognize their value requires a better understanding of these systems, their various types, and their various applications.

Product Information

Product Information

PTO Shaft

The power take-off (PTO) is a sophisticated mechanism, allowing implements to draw energy from the engine and transmit it to another application. It works as a mechanical gearbox which can be mounted on the vehicle’s transmission.

The power take-off shaft (PTO shaft) is a critical component, designed and manufactured for continuous heavy-duty use. A good PTO shaft should be strong enough to bear the torsion and shear stress and minimize vibration.

Setforge, the forging subsidiary of Ever-Power Group, manufactures cold extruded PTO shafts for all types of agriculture vehicles. Our PTO shafts offer great dependability and durability during daily use.

EP Group has been internationally recognized as a reliable global supplier. Our state-of-the-art manufacturing process and experienced engineers ensure the top-quality of all Farinia components.

| After Warranty Service | Video technical support |

| Applicable Industries | Manufacturing Plant |

| Local Service Location | Italy |

| Showroom Location | Italy |

| Warranty | 1.5 years |

| Type | Shafts |

| Place of Origin | China |

| China | Zhejiang |

| Brand Name | EPG |

| certificate | CE |

| Material | Metal |

| Color | Yellow&Black |

| Processing of yoke | Forging |

| Processing of tube | Cold drawn |

| Design | Customized |

| Certificate | CE Certificate |

Product Display

Product Display

PTO Drive Line Gen …

Tie Rod Cylinder H …

Agricultural Gearb …

CompanyInfo

Company Profile

Ever-Power Group

EPG have high-tech machinery and test equipment. We can produce world class high precision products.

Certifications

Certifications

Shipment & Payment

Our Advantages

A: Your inquiry related to our products or prices will be replied in 24 hours.

B: Protection of your sales area, ideas of design and all your private information.

C: Best quality and competitive price.

……

faq

FAQ

1) How can I place order?

A: You can contact us by email about your order details, or place order on line.

2) How can I pay you?

A: After you confirm our PI, we will request you to pay. T/T (HSBC bank) and Paypal, Western Union are the most usual ways we are using.

……

Agricultural China pto shaft cover key in Mangalore India Spraying Implement Self Propelled Locust Boom Sprayer Machine with ce certificate top quality low price

We – EPG Team the most significant agricultural gearbox and pto factory in China with 5 various branches. For more details: Cellular/whatsapp/telegram/Kakao us at: 0086-13083988828

2008 cadillac cts push shaft replacement lemon shaped pto shaft Underneath kubota pto shaft the new holland br780 pto shaft direction rear propeller shaft of john deere 4630 pto shaft removal managerial 2 piece driveshaft sense 04 gto driveshaft of farmall cub pto shaft “Serving tractor pto shaft for sale agriculture, scoring a accomplishment by means of quality of goods and honesty in organization”, our goods have been trusted by consumers and have received a more substantial share of market.

3WPZ-1200G type self propelled spray boom sprayer

3WPZ-1200G collection of sprayer is appropriate for spraying the medicament for the planter of bean, corn, cotton, grain.

Also for garden,fruiter,vegetable, road side tree. The potential could be 1200L, the spraying width could be 16m with 53hp.

Positive aspects:

•This variety of growth sprayer is a tractor mounted sprayer.

•Wide doing work scope,spraying for bean,cotton,corn and so forth.

•Wide spraying with to be 16m max.and the working angle of this tractor sprayer could be altered.

•The capacity of mounted increase sprayer could be adjusted to fulfill various want from the user.

| Model | 3WPZ-1200G self-propelled spray increase sprayer | Pump Variety | Plunger pump |

| Engine Model | 4L68 (Changchai) turbocharged EPT motor | Pump Model | OS-5200 |

| Power / Speed | 53 hp 2400r / min | Pump Stress | 0-45kgf/cm² |

| Displacement Degree | China III | Pump Stream | 220-240L / Min |

| Gear | Forward gear 4,reverse equipment 1 | Pump Speed | 600-800r / min |

| Drive Manner | Four-wheel generate | Tank Potential | 1500L |

| Steering Manner | Hydraulic steering | Spray Height | 0.five-three. m |

| Mixing Technique | Circulating water mixing | Nozzle Design | No.3 |

| Folding Technique | Hydraulic folding | Spray Angle | 110° |

| Spray Width | 16 m | Nozzle Movement | 1.2L / min |

| Ground clearance | 1.eight m(customizable) | System Perform Strain | 0.three-.5Mpa |

| Wheel Keep track of | 1.ninety five-two.6 m(adjustable) | 3 Filtration System | Tank inlet, pump inlet, nozzle |

| Operating Performance | 21-thirty acres / hour | Battery | 12v / 120AH |

| Walking Velocity | ≤25Km / h | Front Tire Design | Tractor tires nine.5-24 |

| Overall Dimension | 5800 mm x 2900 mm x 3700 mm | Rear Tire Model | Tractor tires 9.five-24 |

| Weight | 3811Kg | Water Tank | 15L |

Q:Are you a manufacturing unit or trading organization?

A:We are a manufacturing unit.

Q: How does your manufacturing unit do relating to quality manage?

A: Quality is priority. we always say great significance to high quality controlling from the really commencing to the quite stop.

Q: Do you have a item accessory?

A: Yes, we have the add-ons of the solution.

Q:Can you personalize the merchandise?

A:We can customise the item.

Q: What’s your payment terms?

A: Payment terms is T/T or L/C,We accept all reasonable payment.

Q: How about delivery time of your machine?

A: The delivery time is in 60 working days. It depending your quantity.

Agricultural made in china Machine Tractor Pto Drive Shaft Overrunning Overrun Ratchet Friction Clutch Torque Limiter

Our merchandise are produced by contemporary computerized machinery and gear.a specialised provider of a total selection of chains, sprockets, gears, equipment racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Swift Particulars

- Warranty:

-

1.five several years

- Applicable Industries:

-

Production Plant

- Soon after Guarantee Service:

-

On-line help

- Nearby Support Area:

-

None, Italy

- Showroom Spot:

-

Italy

- Location of Origin:Zhejiang, China

- Brand name Identify:

-

OEM

- certificate:

-

CE

- Substance:

-

Metallic

- Processing of yoke:

-

Forging

- Design:

-

Tailored

- Certification:

-

CE Certificate

Provide Capability

- Provide Ability:

- 10000 Piece/Pieces per Thirty day period

Packaging & Supply

- Packaging Specifics

- wood situation/iron crate

- Port

- ningbo or shanghai

On-line Customization

Product Data

Merchandise Details

PTO Shaft

The electrical power take-off (PTO) is a sophisticated system, making it possible for implements to draw energy from the engine and transmit it to an additional application. It operates as a mechanical gearbox which can be mounted on the vehicle’s transmission.

The electrical power consider-off shaft (PTO shaft) is a vital ingredient, developed and made for steady heavy-duty use. A good PTO shaft should be sturdy enough to bear the torsion and shear anxiety and lessen vibration.

Setforge, the forging subsidiary of Ever-Energy Team, manufactures cold extruded PTO shafts for all kinds of agriculture autos. Our PTO shafts supply excellent dependability and longevity for the duration of every day use.

EP Group has been internationally identified as a reliable worldwide supplier. Our point out-of-the-artwork producing approach and knowledgeable engineers make sure the top-high quality of all Farinia elements.

| Right after Guarantee Provider | Video clip specialized assist |

| Relevant Industries | Production Plant |

| Nearby Provider Place | Italy |

| Showroom Location | Italy |

| Guarantee | one.five years |

| Location of Origin | China |

| China | Zhejiang |

| Brand name Name | EPG |

| certificate | CE |

| Materials | Steel |

| Processing of yoke | Forging |

| Style | Custom-made |

| Certificate | CE Certificate |

Product Display

Solution Display

PTO Generate Line Gen …

6″ Rock Auger

Tie Rod Cylinder H …

CompanyInfo

Organization Profile

Ever-Electrical power Team

EPG have high-tech machinery and examination tools. We can make world course higher precision products.

Certifications

Certifications

Shipment & Payment

Our Rewards

A: Your inquiry relevant to our products or rates will be replied in 24 hours.

B: Security of your product sales location, suggestions of layout and all your non-public details.

C: Best good quality and aggressive value.

……

faq

FAQ

1) How can I location purchase?

A: You can make contact with us by electronic mail about your order specifics, or place get on line.

2) How can I pay out you?

A: Following you confirm our PI, we will ask for you to pay out. T/T (HSBC lender) and Paypal, Western Union are the most normal approaches we are using.

……